The barrel electroplating production line is an automated plating system specially designed for small- to medium-sized bulk parts. Through the continuous rotation of the plating barrel, the workpieces tumble inside the solution, ensuring a uniform and consistent coating.

With years of expertise in equipment design, manufacturing, installation, and maintenance, Dongguan Yueqian Technology provides complete barrel-plating line solutions tailored to customer needs.

Barrel plating equipment offers high processing capacity, low operating cost, high automation, and stable operation, making it the mainstream plating method for fasteners, hardware components, and small metal parts.

It is suitable for zinc, nickel, copper, tin, silver, gold, chrome, and many other electroplating processes.

| Industry | Typical Workpieces |

| Hardware & Fasteners | Screws, nuts, washers, springs, pins |

| Electronics | Small connectors, miniature metal parts |

| Toys | Small metal components |

| Furniture | Small decorative fittings |

| Automotive | Small fasteners and metal accessories |

| Machinery | Small shafts, bushings, sleeves |

Barrel plating is especially suitable for workpieces that are:

✔ Small in size

✔ Large in quantity

✔ Not sensitive to collision

✔ Require highly uniform coating

✔ Processed in continuous, repetitive batches

1) Barrel Plating Machine (Barrel Drum)

Hexagonal or octagonal design

PP, PVC, PVDF corrosion-resistant materials

Optional cathode conduction system

Custom capacities (20L–200L)

Feature:

The tumbling motion ensures thorough turning of parts, resulting in highly uniform plating.

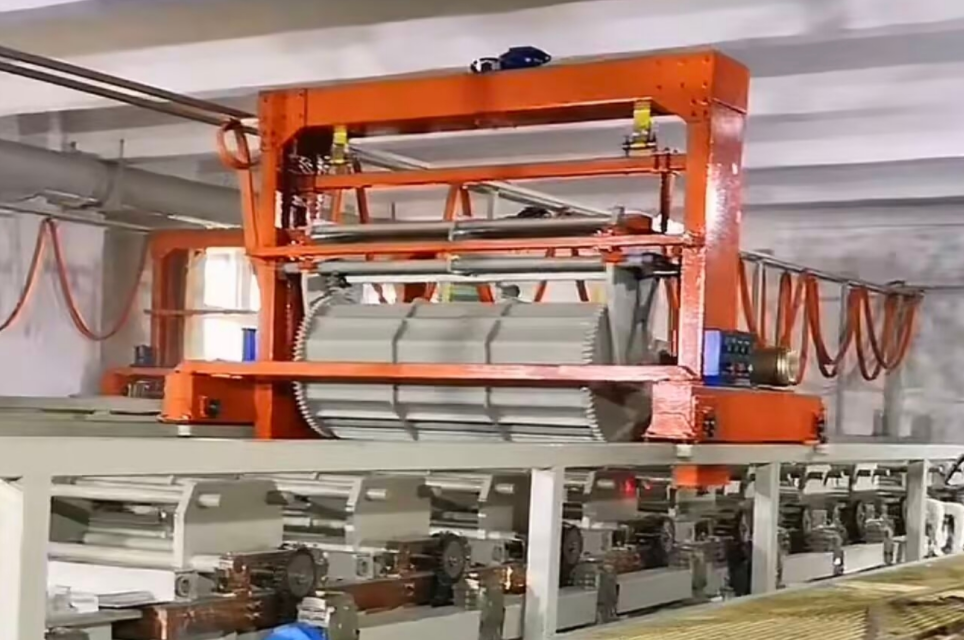

2) Automatic Hoist & Transfer System

Automatic lifting mechanism

Inverter or servo control

Multi-station synchronized operation

Stable and low-noise design

Function:

Transfers the plating barrels through each process tank automatically, enabling continuous batch processing.

3) Plating Tank System

Includes:

Degreasing tank, acid pickling tank, activation tank, plating tank, rinse tanks, etc.

Material options: PP, PVC, steel-lined plastic

Options: heating rods, filtration circulation, air agitation

4) Control System (PLC Full Automation)

Touchscreen HMI operation

Recipe management

Automatic control of current, time, and temperature

Intelligent alarm functions

MES system connectivity available

5) Auxiliary Systems

Filtration units

Automatic dosing and solution replenishing

Dryers / centrifugal dryers

Exhaust and fume treatment systems

Central heating and temperature control

Water circulation & energy-saving systems

Loading

→ Degreasing

→ Rinsing

→ Acid Pickling

→ Rinsing

→ Activation

→ Rinsing

→ Zinc Barrel Plating

→ Rinsing

→ Passivation

→ Rinsing

→ Centrifugal Drying

→ Hot Drying

→ Unloading

The process flow can be adjusted for nickel, tin, copper, and other plating types.

1) Lower Cost, Highest Cost-Performance

Barrel plating offers a simple structure, stable automation, and one of the lowest operating costs in the electroplating industry.

2) Large Batch Capacity, High Efficiency

Each barrel can load a large number of parts, enabling high-throughput, continuous production.

3) Excellent Coating Uniformity

Continuous tumbling minimizes uneven coating thickness.

4) Ideal for Small, Simple Workpieces

Fasteners and small hardware components benefit most from barrel plating.

5) Adjustable Automation Level

Options: manual, semi-automatic, or fully automatic

Fully automated systems allow mechanical loading, hoisting, transfer, and unloading.

6) Eco-Friendly & Compliant

Individual tank fume extraction

Central exhaust treatment

Water circulation and recycling

Solution monitoring to reduce waste

Item Specification Range

Barrel capacity 20–200 L

Batch weight 10–200 kg

Travel speed 8–20 m/min

Lifting speed 4–15 m/min

Automation level Manual / Semi-auto / Fully automatic

Barrel material PP / PVC / PVDF

Production capacity 10–50 batches per hour (depending on process)

✔ Automatic loading/unloading

✔ Automatic weighing system

✔ Automatic barrel opening/closing

✔ Automatic barrel tilting

✔ Online solution monitoring & auto dosing

✔ MES industrial data management system

✔ Energy-saving upgrades (heat recovery / water recycling)

Core benefits delivered to customers:

30–80% increase in production capacity

50–70% reduction in labor requirements

Significantly reduced operating cost

Stable coating quality, fewer reworks

Ideal for high-volume orders

Compliant with RoHS, REACH, and international environmental standards

Barrel plating is an essential automated production solution for fastener factories, plating service providers, and export-oriented manufacturers.

Sample analysis

→ Process testing

→ Layout & 3D design

→ Equipment manufacturing

→ On-site installation

→ Trial run & optimization

→ Production handover

→ After-sales service & long-term support